KAMAL ENVIROTECH P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to KAMAL ENVIROTECH P.LTD.

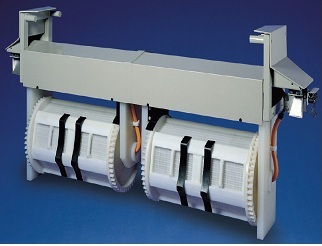

Electrocoat And Ced Tubular Side Anode Cells

Kamal Envirotech are manufacturer and supplier of Anode Cell for Electrocoat/CED Coating in a wide variety of qualities, dimensions and options; the ideal mix of product properties can be optimized for each individual electrocoat plant.

Kamal Tubular Anode Cells combines maximum anode cell operating efficiency by using Anolyte Circulation System. Anolyte Circulation Systems circulate the anolyte across the anode which maintains chemical balance in paint bath by removing paint acid and other anions in the paint bath

Titanium Mmo Anodes

Chemical Properties

The base structure of this type of anode is Titanium, and its surface is covered with various kinds of platinum group precious metal oxides. This precious metal oxide layer work as catalyst for oxygen evolution, and it has good characteristics, such as insolubility and dimensional stability.

Merits of TiO2 electrode over Stainless or Ferrite Anode

• Stainless anode dissolves itself during oxygen evolution.

• The single potential of ferrite anode is higher than that of TiO2, and it requires surplus electric power compared to TiO2 type bare electrode.

• TiO2 electrode has a quick response at the beginning of the operation.

• The peak current of TiO2 electrode is twice that of conventional membrane electrodes. These characteristics allow minimizing the total anode area.

Recifier For Electroplating And Electrocoating And Painting

Description / Specification of Recifier For Electroplating And Electrocoating And Painting

We are involved in offering a wide range of Recifier For Electroplating And Electrocoating And Painting to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Recifier For Electroplating And Electrocoating And Painting. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Fume Exhaust System

KAMAL offers a diverse range Fume Extraction which is generally applicable to all types of production units. As the name suggests, this Fume Extraction is used to extract fume from various industrial chimneys. We manufacture various standard and customized Fume Extraction according to the customer's needs and specifications.

All components are made from corrosion-resistant thermoplastic material. Scrubbing the exhaust air prevents the release of aggressive and harmful vapors into the environment. Vapors and gases are absorbed in the scrubbing liquid and returned to the circuit. The most important basis for calculations are the determination of the exhaust air volume and the dependence of the pre-treatment plant. All the calculations are performed by program modules developed by KEPL.

Spray Nozzles

Specification

-Clamp Size: 1”

- Material of Construction: PP

- Pipe Open Dia: 14mm

- Spray Pattern: Flat Fan, Full Cone, Hollow cone.

Features

-Adjust with hand, no need of tool.

-Chemical corrosion and wear resistance. Resistant to high temperature is 80 degrees.

-Quick & easy cleaning

Application:

-Plating pretreatment cleaning

-Coating pretreatment and chemical cleaning

-Electrophoresis pretreatment spray

-Fume Scrubber

-Surface treatment of degreasing phosphating

-Other low voltage application and chemical spray

Mixing Jet Nozzle Mixing Eductors

Mixing Jet Nozzle, Mixing Eductors are used to agitate or mix Liquids stored in tanks, pits, or sumps. Mixing Eductors use a unique venturi design which enables smaller pumps to circulate large volumes of tank solution.

Design Features:

• Nozzle Materials: PP (polypropylene).

• Nozzle Structure: one-piece construction without internal parts.

• Spray Patterns: Mixing Jet.

• Spray angles: from 40 to 110 degree.

• Pressure Range: 1 to 4 bar (20 to 127 L/min).

• Inlet Thread: 1/4", 3/8", 1/2", 3/4".

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.